This essay is reproduced here as it appeared in the print edition of the original Science for the People magazine. These web-formatted archives are preserved complete with typographical errors and available for reference and educational and activist use. Scanned PDFs of the back issues can be browsed by headline at the website for the 2014 SftP conference held at UMass-Amherst. For more information or to support the project, email sftp.publishing@gmail.com

No Hands Touch the Land: Automating California Farms

by California Agrarian Action Project & Yolo Friends of the Farmworkers

‘Science for the People’ Vol. 10, No. 1, January/February 1978, p. 20–28

Up until last summer, Flavio Martinez made his living in the cannery tomato fields of the Sacramento Valley. Though he found work thinning and weeding tomato plants, picking apricots, or gathering prunes and walnuts, he earned most of his annual income in the eight weeks of the tomato harvest.

For ten to twelve hours each day, seven days a week, he stood shoulder to shoulder with other workers on the harvest machines, pulling rocks, vines, green and rotten fruit from the deluge of tomatoes that raced by on a conveyor belt. Despite the heat, he wrapped his head in a bandana and a hat, as protection against the noise and swirling dust.

When his family was young, it was a struggle to earn enough to feed six children, but in recent years his two oldest sons joined him on the machines, helping to support the family.

Last July, he returned to the ranch where he had worked for the last eight years. The ranch foreman told him there was no work. The harvest machines had been outfitted with electronic eyes which could sort out the green tomatoes. The sorting crew was being cut from 20 workers to 5.

Martinez spent most of the harvest season driving from ranch to ranch in search of work. Everywhere he heard the same story – no sorters needed because of the electronic eyes.

Electronic eyes sorted tomatoes in the place of 5,000 California farmworkers during the harvest of 1976.1 Those lucky enough to find work had to accept a 25 cent an hour wage cut.

“In four or five years, every harvester in the state will be equipped with an electronic sorter,” predicts Jack Deets, a corporate executive with sorter manufacturer AMF Inc.2 Priced from $50,000, the new electronic device uses infrared lights and color sensors to tell a green from a ripe cannery tomato.

Photo-electric color sorting was first applied to farm machinery by John Powers, a professor of agricultural engineering at the University of California at Davis.3 In August of 1976, 250 of the unemployed tomato workers picketed UC Davis to protest the public subsidy that supports mechanization research.4

Migrant workers were the hardest hit by displacement. Their meagre savings had been spent on the trip north to the tomato harvest. They became trapped, penniless, with dismal prospects for work.

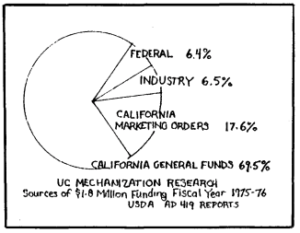

Jobless families moved in with their friends and relatives. In the government-run migrant camp at Madison, California, two-thirds of the families were living doubled up, according to Ross Parker, director of the Yolo Housing Authority. With 12 to 15 people living in each 3 room cabin, water and sanitary facilities were pushed to their limit.5

Last summer’s harvest revealed what may prove to be a serious shortcoming of the electronic sorter. While the sorter worked efficiently at the beginning of the harvest, when most cull fruit was green, human hands and eyes were needed at the end of the harvest when it is overripe and rotten tomatoes which must be discarded.

The harvest was still dependent on thousands of migrants, but their work was cut from eight weeks down to one or two weeks of harvest employment. Mar Lynn Ormbsy, a demographic analyst for the California Department of Housing, says that mechanization causes “gaps in the traditional south to north itinerary – no longer [are there] ‘back to back’ harvests to provide continuous work”.6

With mechanization, the farmworkers’ work year is cut, reported UC Berkeley agricultural economist William Metzler, who added, “reliance on Welfare Department assistance has become part of the annual life pattern of many farm families”.7

“We have worked hard for these growers all our lives,” says Flavio Martinez. “When they brought tractors to pull the plows, they cut the horses’ necks and ate horsemeat. That might be a kinder end than the future that they are preparing for us.”

Social Sleepwalking

In the heart of the Sacramento Valley processing tomato district is the nation’s largest center for agricultural research, the Davis campus of the University of California. UC scientists say their $50 million annual research budget pays for a cornucopia of technology that benefits consumer, farmer and farmworker alike. The mechanization of the tomato harvest is cited as one of their greatest accomplishments.

“Mechanization is one of the chief research missions of the University of California,” UC Information Officer Ray Coppock reported to the California legislature in 1966.8 There are now 22 mechanization projects in progress at Davis, while an additional 7 projects are underway at the UC campus at Riverside.9

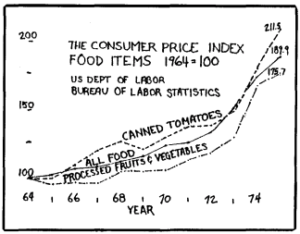

Public funds pay 93% of the $1.8 million annual cost of these projects, which are aimed at eliminating most of the 176,000 harvest time jobs in California. The research involves scientists in several disciplines working in co-operation.

Research to mechanize the cannery tomato harvest conducted in the early 60’s is a good example of the multi-disciplinary team effort. University scientists bred a thick-skinned tomato, devised precision planting systems needed to grow it, tested the chemical that could ripen it, and built the machine to harvest it.10

Typical of the engineering studies underway is the development of a mechanical lettuce picker by Davis professor Roger Garrett. The machine uses a gamma ray selector to identify which lettuce heads are mature enough for harvest. A gattling gun packing device wraps the heads in plastic mesh.

New crop varieties are being bred to match the mechanical pickers. Davis geneticist Harold Olmo is trying to breed a new raisin grape variety that will dry without being cut from the vine. Says Olmo, “This may lead to direct mechanical harvest and eliminate all hand harvest labor.”

University scientists are studying the problems in processing mechanically harvested produce. Wine chemist Cornelius Ough is analysing the “leafiness aroma” in wines made from mechanically harvested grapes. His research will be useful in setting standards for the amount of leaf trash that mechanical grape pickers can be allowed to mix into wine grape loads.

The mechanization developments were criticized at the hearings on the UC budget held by the California Assembly in April. “In a time of such high unemployment, it is inconceivable that the state is spending the taxpayers’ money to put more people out of work,” UFW spokesperson Michael Linfield told an Assembly committee. He asked that a moratorium be called on labor displacing research until studies are made on the social impact of the projects, and until the state makes provisions to compensate displaced workers.

None of the University’s 1500 agricultural scientists is analysing the impact of UC research, admitted James Kendrick, UC Vice-President of Agricultural Sciences. “Our primary mission is concern for the production of food and fiber,” he told the committee.

William Friedland, a rural sociologist at UC Santa Cruz, calls the University’s approach “social sleepwalking.” He wants to study the effects of Garrett’s lettuce harvester. The University administration, however, feels that no study of the impact of mechanization is needed, and so will not fund Friedland’s work. He has been forced to abandon his research.

Tough Tomatoes

Every American consumer knows about the new flavor in canned tomatoes. “They taste like rubber,” remarked California State Senator Walt Stiern (D-Bakersfield) at a recent hearing on the UC budget.

Davis Professor G.C. “Jack” Hanna bred a thickskinned tomato to withstand the rigors of mechanical harvest. Called VF-145, Hanna’s tomato was not tough enough. In 1968, he reported that a quarter of the crop, some 1 million tons of VF-145, was damaged with impact cracks contaminated with soil, yeast, and bacteria.11

University breeders have developed an even tougher “square round” tomato. To be precise, the tomato is not square like a box, but in the words of tomato specialist William Sims, “it’s more square than round”.12 Named UC-82, the new tomato is a thick-walled and juiceless fruit, but it can withstand the high speed operation of harvesters equipped with electronic sorters.

Coby Lorenzon was the Davis engineer who designed the machine that could pick Hanna’s tough tomatoes. His harvester was designed for large scale farms. “Usually about 125 acres may be planted per harvest machine for the beginning grower,” Sims explained, “and up to 200 acres for the more experienced grower”.13

The average farmer at the time planted 45 acres of cannery tomatoes. Most could not get the financing. necessary to triple their acreage and buy a $25,000 harvester. Within 10 years, the University scientists unwittingly forced 85% of the state’s 4,000 cannery tomato farmers out of the business.14

The remaining growers then expanded their tomato plantings to an average of 350 acres. Once committed to making payments on their new tomato harvesters, they could no longer be flexible in deciding how much to plant. In recent years there has been chronic overproduction in the tomato industry. 1.8 million tons of fruit were left to rot in California fields in 1976 alone.

Large tracts of land are needed to grow tomatoes for machine harvest. Sims advises growers that “row lengths of less than 600 feet seriously decrease harvest efficiency.” The larger the field, the less the time lost in turning the machine from one row to another. As a result, mechanization has concentrated the tomato industry in the few California counties with such large tracts of land.

Pests spread rapidly in the tomato monoculture, necessitating the virtual fumigation of tomato districts with more than four million pounds of pesticides each year.

In the rest of the United States, where there are no huge, uniform tracts of tomato land, tomato acreage is declining. A handful of California canning corporations now pack 85% of the nation’s tomato products.

“The mechanized tomato has led to increased corporate concentration in the processing industry,” claims consumer advocate Al Krebs. The Western Director of the Agribusiness Accountability Project, Krebs told the California Assembly in April that the state’s top four canning corporations now control more than 80% of tomato processing, a situation he termed “tight oligopoly.”

It is true that mechanization did cut the cost of producing cannery tomatoes by $7.25 a ton, according to a study made by UC farm advisor Phillip Parsons.15 Had this savings been passed on to the consumer, mechanization would have lowered the retail price of a can of tomatoes 3%.

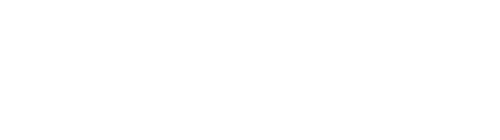

But since 1964, the year before the tomato harvest was mechanized, the retail price of canned tomatoes increased 111%, according to statistics compiled by the U.S. Department of Labor. By comparison, the retail price of food went up only 90%, and the price of processed fruits and vegetables went up only 76%.16

Between 1970 and 1975, the profits of the processors soared. H.J. Heinz profits went up 104.7%, while Del Monte profits increased 228.9%.

Consumers were not only stuck with high prices and a tough tomato, but as taxpayers they had paid for the research that made it all possible. They continue to subsidize mechanization by paying a number of hidden costs.

One such cost involves a simple failure of the harvest machine, which collects not only tomatoes, but substantial quantities of dirt as well. Dirt and trash removal cost processors $75 million in 1975. The California Tomato Growers Association warns that processing plants will close if municipal sewerage systems do not expand to handle the cannery effluent.17 California, though hard hit by drought, will still be using millions of gallons of water to wash dirt from machine-harvested tomato loads.

Mechanizing the tomato harvest eliminated 32,000 picking jobs in California,18 and thousands more cannery and farm jobs in Ohio, Indiana, and New Jersey. Tens of thousands more California farmworkers have been displaced in the mechanization of the prune, nut, sugar, beet, and wine grape harvests.

Increased social welfare payments, the migration of jobless farmworkers to American cities, and the decline of small farms and rural communities must be figured as “hidden costs” of mechanization.

“Hard tomatoes and hard times,” are the products of mechanization research, wrote the Agribusiness Accountability Project in 1972, adding that “in terms of wasted lives, depleted rural areas, choked cities, poisoned land and maybe poisoned people, mechanization research has been a bad investment”.19

Conflicts of Interest

The California Assembly wants the University to reevaluate its commitment to mechanization research. A rider was attached to the Assembly version of the UC budget, requiring that “social impact reports” be prepared to assess the effects of labor displacing agricultural research.20

UC Vice-President Chester Me Corkle opposed the reports, and asked that agricultural researchers be allowed to retain their “freedom of inquiry.” Intense lobbying by the University caused the legislature to delete the rider from the final version of the budget.

Don Villarejo, a lecturer at UC Davis and activist with the California Agrarian Action Project, questioned whether such “freedom of inquiry” actually exists. Villarejo testified at the April Assembly hearings about the social and economic interests of UC decision makers.21 He reported that McCorkle sits on the Board of Directors of Del Monte Corporation, a major beneficiary of mechanization research, as does Edward W. Carter, a member of the University’s Board of Regents.

William K. Coblentz, Chairman of the Board of Regents, is also the managing partner of ASA Farms, the corporate owner of a million -dollar parcel of tomato crop land of Yolo County.

While “freedom of inquiry” is said to govern professors’ decisions about what to research, the University’s Regents and Administrators have set up an agricultural research system that involves private interests in the decision-making. The University employs professors, provides them with lab space and clerical help, but allocates little or no money to pay for research staff and supplies. Professors must seek outside funding to meet these costs.

According to a study by Isao Fujimoto at UC Davis, the outside funding agencies have the greatest influence on what research is undertaken.22 In this way a tax deductible dollar donation determines how four dollars worth of University research is conducted. Private donors such as farm associations, canners, and chemical companies used to be the primary source of outside funding for mechanization research.

In recent years, agribusiness interests have become reluctant to donate even the single dollar. They have turned to marketing orders to generate research funding. Under the California Marketing Act, a law authored by UC Professor E.A. Stoikdyk,23 growers or processors can join together to form a marketing order, and impose a state tax on a specific agricultural commodity. They then choose the members of an Advisory Board, which allocates the revenues to advertising, market surveys, or University research.

Provisions of the law have allowed a small number of large producers to vote a commodity tax on all the rest. Only 49% of California’s wineries voted in favor of the Wine Advisory Board,24 but the fact that Gallo and United Vintners make 75% of California’s wine allowed them to push the tax through. It also allows these large producers an essential veto over Advisory Board activities.

University personnel have been instrumental in establishing these lopsided boards. The Wine Advisory Board was organized by a “Campaign Committee” headed by UC Professor R.L. Adams. Four newly organized research marketing orders were organized through the joint efforts of the Western Growers Association and UC Davis Dean Jim Lyons, who received a $2,500 research grant from the WGA. WGA members make up most of the Advisory Board members of these marketing orders, which are managed by a former WGA employee.25

University professors must agree to the detailed terms of a research contract in order to receive market order funds. Although the bulk of UC mechanization development costs are paid by public funds, it is private interests that dictate that the research be done.

Machines Won’t Strike

It is ironic that California farms can produce $9 billion of food and fiber each year, yet still not adequately provide for those who till the land and harvest the crops. With few independent family farmers in California, most work is done by migrant laborers who travel from one farm factory to another. Chronic high unemployment has meant that workers must accept a wage that has averaged only 40% of an industrial worker’s pay, and be thankful to have any job at all.

Low wages have hurt the relatively few small-scale family farmers. The farmer who drives his own tractor must compete against a factory farm where laborers do the same work for little pay.

In 1918, Richard Adams, a professor of agricultural economics at UC Berkeley, wrote the report that has set the trend for 60 years of University thinking. When farmworkers’ wages increase, he said, it is evidence of a labor shortage.26

While other industries have paid good wages to insure an adequate labor force, California farm industrialists have relied on the government to recruit immigrant workers. Adams campaigned for the immigration of Filipino and Mexican workers in the 20’s. The importation of Mexican workers during World War II, the forerunner of the Bracero program, was administered by 125 University farm advisor offices.27 UC economists opposed the end of the Bracero program in 1965.28 29

Farmworkers have made repeated attempts to form unions in order to bargain for higher wages. They have been kept divided, however, by an agricultural system that assigns jobs and wage rates on the basis of race.30 In his text Farm Management (1921), Adams taught University agriculture students that different races were suited to different farm jobs. “The colored man,” wrote Adams, is “home-loving and gregarious,” and can work hoeing, planting and weeding. He reported that the Mexican “peon” is “childish and lazy” and good only for cheap hand labor. The Japanese are good squat laborers, while the “lean, lanky and ennervated” Hindu workers were suitable for hand work in the beet, celery, and rice fields.

When unions are formed, the University sides with employers. In 1933, S. Parker Frisselle, manager of the UC vineyards at Fresno, organized and became the first President of the Associated Farmers, a group formed to oppose farm worker unions.31 With the help of University Farm Advisors, thousands were recruited into the organization. By 1937, they were organized into a vigilante army that attacked picket lines, burned strikers’ camps, and kidnapped union organizers.

In March 1977, the University Extension offered farmers a one-day class on California’s new farm labor law. George Daniels taught the growers how to wage “psychological warfare” in order to beat the United Farmworkers in union representation elections.32

Mechanization is the University’s current answer to the labor problems of farm factories. As tomato breeder Jack Hanna explained it, “I’d seen nationality after nationality in the fields, and I felt that some day we might run out of nationalities to do our hard work”.33

Mechanization has been a disaster for small-scale operators already being forced out of business by increasing capital costs. UC Information Officer Ray Coppock offered them a simple choice: “Mechanize or sell out”.34

University-developed machines not only combat the “labor shortage” in California agriculture, but they provide large growers with insurance against unionization. When United Farmworkers’ President Cesar Chavez led 8,000 Salinas Valley workers out on strike in 1970, the lettuce growers gave the University $13,500 to build a mechanical lettuce picker. Roger Garrett, the engineer who built the machine, cited the value of his invention in this way: “The machine won’t strike, it will work when they [the growers] want it to work”.35

Another University engineer, Mike O’Brien, tested his melon harvest machine during a UFW melon strike in West Fresno County in 1973.36 Charles Hess, Dean of Agriculture at UC Davis, told a reporter why growers are so appreciative of the University’s mechanization research. “The thing that drives growers to mechanize,” he said, “is the fear of a strike”.37

Hard Times

Born in Mexico, Flavio Martinez first came to California as a Bracero, a temporary immigrant allowed in the state for only the few weeks of the tomato harvest. Under the Bracero program, the U.S. government brought growers a virtually unlimited supply of workers from the poorest areas of Mexico.

“They paid us 10 cents to fill a 50-pound box with tomatoes,” he recalls. Depending on the field, he could earn about 70 cents to a dollar an hour. California industrial workers earned an average of $2.50 to $3.00 an hour at that time.

Martinez legally immigrated to the U.S. in 1957. Though he married and began to raise a family, he had only seasonal work and Bracero wages to meet the high cost of living in California. The wage rate for picking tomatoes remained unchanged for a decade.

Martinez remembers the harvest of 1965 with nostalgia. In that year Congress ended the Bracero program, and the piece rate wage for tomato picking jumped. It appeared that the high wage would soon attract enough pickers to the tomato fields to compensate for the absence of Braceros.

That same year the mechanical harvester was introduced. While hand pickers could work their own pace, the sorters were tied to the pace of the machine, and could rest only when it stopped. Sorting was not skilled work; in fact here was much more skill involved in being an efficient hand picker. Growers paid sorters $1.40 an hour, a wage that was 25 cents an hour less than the average earned by hand pickers.38

By 1969, 1500 machines harvested California’s cannery tomatoes, and hand picking became a thing of the past. The high wage evaporated, and 32,000 tomato pickers were displaced. Though their productivity had been doubled by the harvest machine, the hourly wage paid to tomato workers remained low, 15 cents to 25 cents below the average California farm wage.

Cesar Chavez’s United Farmworkers of America began an organizing drive in the northern California tomato industry in 1974. Since 1972, the price paid for cannery tomatoes had doubled, from $28.00 to $56.80 a ton.39 Thousands of workers, hopeful that their wages could be increased, signed cards authorizing the UFW to represent them.

In August 1974, the UFW called a strike against cannery tomato growers in the Stockton area. The strike soon spread south into Stanislaus County and west into the Delta area. Further north in Yolo County, a second strike was called against cannery tomato growers at the beginning of September. Five hundred more workers walked out of the fields.

The growers raised wages 50 cents an hour in an attempt to get workers to abandon the strike. When the harvest ended, the strikers called the wage increase a victory, but no contracts had been signed.

California’s new farm worker election law was enacted the next year. In the midst of the election campaigns, tomato growers raised wages above $3.00 an hour in order to win a no-union vote from workers. The workers’ memory was not so short. The majority of workers on some 20 tomato ranches voted for UFW representation.

The tomato growers have turned to a second generation of University-developed technology, electronic sorting. Thousands of workers were displaced as the 1976 wages were lowered to $2.75 an hour.

The UFW has been negotiating contracts with a group of five tomato growers in the Delta area. Only a single major issue, that of a mechanization clause, remained to be resolved when negotiations between the UFW and one grower, Kline Ranches, broke off in May. Kline employees who were at work harvesting asparagus walked out on strike. To date, the strike continues, with the company holding out for its unilateral right to mechanize tomato harvest operations. The union wants mechanization to be subject to negotiation.

Bernell Harlan, who grows 800 acres of tomatoes in Yolo County, explains his move to electronic sorting in quite simple terms- he wanted to stop unionization of his workforce.

Many of Harlan’s 155 employees joined the UFW strike in 1974. He responded by fitting his five harvest machines with electronic sorters, cutting all but 44 workers from his payroll.

“It required a stiff capital investment,” says Harlan, who admits electronic sorting is more costly than hand sorting. He feels it was worth the extra cost because ”one of the big advantages of these machines is you can keep the people you want, and get rid of the trouble makers”.40

To Flavio Martinez, the outcome is an old story. “Every time we begin to earn good wages, they bring in a machine to break our bargaining power and keep us poor.”

If a list were made of those who have benefited from the mechanization of the tomato harvest, the name of John B. “Jack” Anderson would belong near the top. A graduate in Agricultural Economics from UC Davis, the 35-year old “king of the cannery tomatoes” farms a 62,000 acre empire that stretches across 5 California counties.

From his headquarters in Davis, Anderson used the UC developed technology to parlay loans from wealthy doctors into the largest tomato ranch in the world, Andco Farms, Inc. In 1974, Andco raised 17,000 acres of tomatoes, worth roughly $25 million and accounting for 7% of the California crop.

Andco employs more than a thousand farmworkers, most of them in the tomato harvest, according to business manager Henry Stone. It is in tribute to the tomato that the corporation’s buses, harvestors, pick-up trucks, combines, and even Anderson’s personal Cadillac and Land Rover are all colored tomato red.

With success in tomato production, Anderson has begun to diversify his holdings. He has bought a rice-dehydrating mill, a trucking company, a 14,000 acre cattle ranch, part of a fertilizer distributorship, and half-interest in a newly built tomato cannery.

Farm equipment manufacturer FMC Inc. loaned Anderson and the T .H. Richards Co. $4.2 million to build the tomato cannery. Cattle from the Andco ranch are fattened on tomato waste in an adjacent feedlot, with the aid of advice from UC Davis scientists. FMC also leases 16 of its tomato harvesters to Andco, 7 of which are being fitted with electronic sorters.

Grievances over company housing caused Andco workers to be among the first to join the 1974 UFW strike. Inspectors from the California Department of Housing found 378 people living in Andco’s Mace 1 labor camp, an average of 6.8 people in each 10′ x 12′ room. Families were cooking on gas fired hot-plates in the same room where they slept. Sinks were located outdoors, the communal showers were usually without hot water, and the broken plumbing leaked raw sewage before discharging it into an open roadside ditch.41

Anderson himself lives in a community built around a golf course, the fashionable El Macero. Two $70,000 houses were joined together to form Anderson’s ranch style mansion. In 1966, Ronald Reagan announced his intention to run for Governor at a press conference held in this sprawling El Macero home.42

Andco workers were among the first to vote under California’s new Agricultural Labor Relations Act. “We campaigned hard for a no-union vote,” said business manager Stone.43 UFW organizer Al Rojas said that Andco used “fraud, threats and intimidation” to dissuade workers from voting in favor of the union.44 Andco workers cast 373 votes for no union and 290 votes for the UFW.

The Agricultural Labor Relations Board held hearings on company conduct before the election. Hearing Officer Bob Covington found that at least eight Andco workers had been fired on account of their support for the UFW. He cited nine counts of company misconduct in recommending that a new election be held.45

However, another ALRB election is unlikely at Andco Farms. Like Bernell Harlan, Jack Anderson has found electronic sorters to be an excellent alternative to unionization.

California’s Agrarian Movement

Community activists have started a service center in Woodland, California, to provide emergency aid to farmworkers displaced by the electronic tomato sorter. Called simply “Centro de Servicios para Campesinos” (Farmworkers’ Service Center), the center sends volunteers door-to-door in the migrant camps and barrios to help farmworkers get food, housing, transportation, and medical attention.

“We need an emergency aid program to help the people who have been put out of work,” says service center director Rosa Villareal. Current government programs, she says, cannot cope with the crisis of thousands of now unemployed farmworkers.

State aid for displaced farmworkers is only in the preliminary stages. Assemblyman Art Torres (D-Los Angeles) has introduced legislation that would create a fund to provide aid. Under his bill, the sale and output of harvest machines would be taxed. Revenue would then be used for extended unemployment benefits, training, and job placement.

The measure, AB 1537, is backed by the United Farmworkers. “The machines must pay their own way,” says UFW spokesperson Michael Linfield, “including the costs of employee displacement.” The bill was tabled in 1977, not to be considered again until sometime in 1978.

Electronic tomato sorters will displace an estimated 24,000 farmworkers, according to the Assembly Office of Research.46 While growers try to farm with fewer farmworkers, farmworkers have been starting their own farms. Resettling displaced farmworkers on the land may prove to be a long term solution towards the problem of returning the unemployed to productive lives.

The Co-operativa Central, in Salinas, California, is one of the more successful farm worker owned and operated farms.47 52 farmworkers’ families, all former sharecroppers and migrant workers, now grow strawberries to earn an average annual income of more than $17,000 per family. The co-op recently bought 700 acres of prime Salinas Valley farmland.

As farm owners, the farmworkers make decisions to insure not only maximum profit for the farm, but also maximum work and wages for its employees.

Land is central to California’s new agrarian movement. A Fresno based group, National Land for People, is pressing for the enforcement of Federal Reclamation Law in the 570,000 acre Westlands Water District. A $2 billion water project provides the District’s large corporate growers with cheap irrigation water. The law requires landowners to sell all but 160 acres of their holdings at pre-irrigation land prices, about 25% of current market value. If NLP is successful, thousands of acres of low cost land will become available for farmworkers and small farmers.

In the northern part of the state, the California Agrarian Action Project has found that thousands of acres of farmland, owned by agencies of the State government, are being leased to large growers, often in “sweetheart” arrangements. The Project is asking that these lands be leased to farmworkers, with priority given to those who have been displaced by mechanization.

Crucial to all of these attempts to re-settle farmworkers on the land is the need for adequate financial and technical assistance. The scarcity of credit has forced many recently established farmworker owned farms out of business.

The taxpayer will be subsidizing whatever change is to come. While it is uncertain that mechanization will lower food prices, it is certain that it requires a public research subsidy to automate the farms, and additional millions of dollars of public assistance to support those who are displaced.

The alternative of resettling farmworkers into productive lives on the land would also require a taxpayer subsidy, but the result would be far more attractive than the influx of thousands more into the ghettos of urban poor. California’s farms would not be automated factories, but homes for an autonomous rural people.

This article was originally published as a pamphlet by the California Agrarian Action Project. a group dedicated towards bringing control of California agriculture to those who work the land. The Project does research, public education, and political action. Persons interested in more information should write: California Agrarian Action Project, 1007 Chestnut Lane, Davis, California 95616. Donations are gratefully accepted. The graphics that accompany this article come from the original pamphlet.

>> Back to Vol. 10, No. 1 <<

REFERENCES

- Estimate based on Farm Labor Reports 881-A, a bimonthly report of the California Employment Development Department.

- “Sorting Out the Sorters” Woodland Daily Democrat, February II, 1977.

- “Mechanical Tomato Harvest Founders Honored”, Woodland Daily Democrat, December 29, 1976.

- “Farmworkers Protest UCD Role in Tomato Sorter”, Paul Mapes, Sacramento Union B-4, August 20, 1974.

- “‘Extra’ Families Jam Labor Camp,” Scott Reeves, Woodland Daily Democrat, August 5, 1976.

- “Information Report on Agricultural Mechanization,” Mar Lynn Ormsby, California Department of Housing and Community Development, February 3, 1976.

- “Farm Mechanization and Labor Stabilization,” William H. Metzler, Giannini Foundation Research Report, No. 280, University of California, January 1965, p. 57.

- Research on Agricultural Mechanization 1966, University of California. Division of Agricultural Sciences.

- Based on AD-419 reports of the University of California to the U.S. Department of Agriculture.

- “Advances in American Agriculture: The Mechanical Tomato Harvester as a Case Study,” Wayne D. Rasmussen, Technology and Culture. 9:531-543, October 1968.

- “Breeding Developments for Fruit Vegetables,” G.C. Hanna, et al., p. 242 in Fruit and Vegetable Harvest Mechanization: Technological Implications, B.F. Cargill, G.E. Rossmiller, editors. Rural Manpower Center, Michigan State University, East Lansing, Michigan, 1969.

- “And Now California Develops a Square Tomato,” Robert Lindsey, New York Times. March 8, 1977, p. 33.

- “Mechanized Growing and Harvesting of Processing Tomatoes,” William Sims et al., University of California Agricultural Extension Service AXT-232 January 1968.

- Destalking the Wily Tomato, William Friedland and Amy E. Barton, University of California at Davis, Department of ABS, Research Monograph No. 15, June 1975.

- “Cost of Mechanical Tomato Harvest Compared to Hand Harvesting,” Phillip S. Parsons, University of California Agricultural Extension Service AXT-224, May 1966.

- Handbook of Labor Statistics, U.S. Department of Labor, Bureau of Labor Statistics 1970 (Bulletin 1666) 1976 (Bulletin 1905).

- “Editorial,” California Tomato Grower, p. 3, January 1976.

- Friedland and Barton, op. cit., p. 41.

- Hard Tomatoes. Hard Time.J. Jim Hightower and the Agribusiness Accountability Project. Schenkman, Cambridge, Mass., 1972, p. 39.

- “Legislators Want Reins Placed on UC Spending,” Bob Egelko, Sacramento Bee, May II, 1977.

- “Regents Conflict of Interest Charged,” Jim Dufur, Sacramento Bee, April 3, 1977.

- “What Research Gets Done at a Land Grant College: Internal Factors at Work,” !sao Fujimoto and Emmett Fiske, Department of Applied Behavioral Sciences, University of California at Davis.

- California Farm Organizations: A Historical Study of the Grange, the Farm Bureau, and the Associated Farmers 1929-1941, Clarke A. Chambers, University of California Press, Berkeley, 1952, p. 134-5.

- “Report on Review of Wine Advisory Board and Wine Institute,” Report of the Office of the Auditor General to the Joint California Legislative Audit Committee, August 1973 (186.1), p. 5.

- “Agribusiness and the University: A Profitable Alliance,” Paul Barnett, California Citizen Sun, August 15, 1975.

- “A Study of Farm Labor in California,” R.L. Adams, T.R. Kelley, Circular No. 193, University of California Agricultural Experiment Station, March 1918.

- A report of the Emergency Farm Labor Project of the Agricultural Extension Service 1943-45, University of California Agricultural Extension Service 1946.

- “No Dice for Braceros,” William Turner, Ramparts, September 1965.

- The Dirt on California: Agribusiness and the University, Anne and Hal Draper, Independent Socialist Club of America, Berkeley, c. 1968.

- Factories in the Fields: The Story of Migratory Farm Labor in California, Carey McWilliams, Boston, Little, Brown and Co. 1939, p. 118.

- Chambers, op. cit., p. 40.

- “Growers Told to Offer Workers ‘Better Deal’,” Harrison Wadsworth, Woodland Daily Democrat, March 31, 1977.

- Wall Street Journal, June 17, 1968.

- Research on Agricultural Mechanization 1966. op. cit.

- “UCD Ag Research Lettuce Harvester Could Displace Salinas Farmworkers,” Paul Barnett, California Aggie, May 28, 1975.

- “Melon Growers Exert Influence,” Paul Barnett, California Aggie, May 29, 1975.

- Woodland Daily Democrat, September 13, 1976.

- Hand pickers earned an average of $1.65 an hour. See: “The Domestic Farm Laborer: A Study of Yolo County Tomato Pickers,” James W. Beckett, University of California at Davis, Dept. of ABS, Research Monograph# 2, 1966.

- “Vegetables – Processing,” Annual Report on Processing Tomato Crop, California Crop and Livestock Reporting Service.

- “Electronic Tomato Sorter Values Offered by Yoloan,” Woodland Daily Democrat, January 14, 1977.

- Reports on inspections by the California Department of Housing and Community Development, dated July 25, 1974 and August 9, 1974.

- “Stewart Here: Actor Boosts Reagan Campaign,” Penny Spar, Davis Enterprise, p. 3, July 3, 1976.

- “Workers on Biggest Tomato Farm Vote on Whether to Link with UFW,” Steve Duscha, Sacramento Bee, September 25, 1975.

- “UFW Aide Blames ‘Threats’ for Loss at Andco Election,” Sacramento Bee, September 27, 1975.

- “Andco Must Hold New UFW Election,” Scott Reeves, Woodland Daily Democrat, March 20, 1976.

- “Memorandum on Displacement of Farm Jobs,” Manuel Hernandez, California Assembly Office of Research, June 6, 1977.

- “Managing Workers,” Daniel Zwerdling, Working Papers fora New Society, Vol. II, No.3, Fall 1974.