This essay is reproduced here as it appeared in the print edition of the original Science for the People magazine. These web-formatted archives are preserved complete with typographical errors and available for reference and educational and activist use. Scanned PDFs of the back issues can be browsed by headline at the website for the 2014 SftP conference held at UMass-Amherst. For more information or to support the project, email sftp.publishing@gmail.com

Dying for a Job

by Mandy Hawes

‘Science for the People’ Vol. 12, No. 2, Month 1980, p. 14-17

Mandy Hawes is a lawyer in a community law office in San Jose, Ca. She specializes in occupational health and safety work primarily with unorganized electronics workers in “Silicon Valley”. She is also the Campaign Director for the Electronics Committee on Occupational Safety and Health (ECOSH). (Mandy would appreciate hearing from others doing similar work.)

Between 1964 and 1969 George Zerwas ran a reflux asphalt extractor at a soil-testing company in the Midwest. The procedure called for heating the “universal solvent,” benzene, so that its vapors would pass through an asphalt sample to a condenser, and then drip back down through the sample, separating out impurities. After several hours of repeating this process, George would remove the sample for drying. Twice while George Zerwas was on this job the extractor blew up, leaving him in a benzene “torch.” But even when everything went as scheduled, the benzene vapors were strong: their odor carried to the floor above his basement work site. (The olfactory threshhold for benzene is 1,000 milligrams per cubic meter, or about 300 parts per million. The lower and upper explosive limits for benzene are 1.3 percent and 7.1 percent of total air volume — 1,300 to 7,100 parts per million).

In the spring of 1974 the National Institute for Occupational Safety and Health (NIOSH) issued a “criteria document” on benzene which summarized the substantial body of medical literature accumulated over decades, documenting the association between chronic benzene exposure and dramatically increased leukemia risk. A year later, in May 1975, at age 29, George Zerwas was having back trouble and saw his doctor for some routine diagnostic tests. The results showed a positive diagnosis: acute lymphocytic leukemia.

For a time, George’s disease was kept in remission. By 1977, however, it began to interfere with his ability to work. In April 1979 he entered the hospital for another round of treatment, and although he always intended to return to his job, he was so ravaged by his disease that he was never to return.

Meanwhile, the petroleum industry, together with manufacturers and industrial users of benzene, were engaged in another battle, one in which they were having decidedly more success than George Zerwas was having in his lonely struggle against leukemia. The industrial battle was against the enactment of an emergency benzene standard of one part per million. This standard, promulgated by the federal Occupational Safety and Health Administration (OSHA) in 1978, derived from a mountain of evidence which indicated that this human carginogen needed very strict control. Industry did not try to deny the strong causal link between benzene exposure and a greatly increased risk of leukemia. Rather, they argued that in setting a one part per million standard, OSHA had failed to give adequate consideration to what it would cost American industry to attain it.

Meanwhile, the petroleum industry, together with manufacturers and industrial users of benzene, were engaged in another battle, one in which they were having decidedly more success than George Zerwas was having in his lonely struggle against leukemia. The industrial battle was against the enactment of an emergency benzene standard of one part per million. This standard, promulgated by the federal Occupational Safety and Health Administration (OSHA) in 1978, derived from a mountain of evidence which indicated that this human carginogen needed very strict control. Industry did not try to deny the strong causal link between benzene exposure and a greatly increased risk of leukemia. Rather, they argued that in setting a one part per million standard, OSHA had failed to give adequate consideration to what it would cost American industry to attain it.

The federal courts have thus far sided with the petroleum companies, and OSHA’s emergency benzene standard, issued almost two years ago, may never go into effect. At the moment, advocates on both sides are awaiting a decision from the United States Supreme Court, which heard oral arguments on this cost-benefit issue last October 10, just four days before George Zerwas died of leukemia at the age of 33, leaving a wife and child. To anyone touched by the human tragedy of toxic chemical exposure, arguments about costs and benefits are painful to hear, and the OSHA standard, while gratifying, comes late.

The cost-benefit argument appears repeatedly when industry puts up resistance to improved occupational standards. Under the current standards, industry bears the cost of workers compensation insurance, augmented sometimes by a citation from OSHA. Considering the cost of technological improvements that would be required by tougher standards, it is cheaper for industry to continue exposing workers to carcinogens, mutagens, and other toxic horrors, than to clean up toxic environments. Since it is very hard for workers to prove that their cancers and other disabilities are industrially-induced, it is hard for them to win claims for compensation. While tougher standards, if met, would strengthen industry’s position in compensation cases, by assuring safer environments they would hopefully reduce the number of such cases.

Toxic Substances: The Issue for the ‘80s

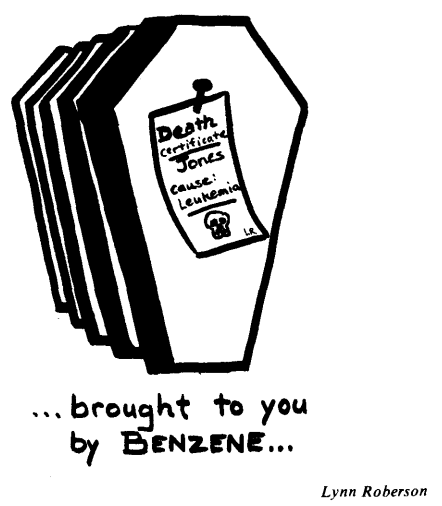

Until chemical manufacturers are taken to task for supplying unsuspecting workers and other purchasers with chemical time bombs, we will all be relying, to our peril, on a philosophy roughly the equivalent of “Better Profits, But Often Worse Living, Through Chemistry.” Even before the question arises of how to control the mind-boggling number of chemicals used in U.S. industry, health advocates clash with industry over the basic questions of whether people have the right to know the name and the perceived hazards of substances with which they are working. Citing everything from supposed trade secrets to the potential confusion that disclosures might produce in the lay public, opponents of workers’ right to know reached a new low when they appealed to the lack of bulletin board space as a reason for not posting information. They argued that since no plant could possible post all the material safety data sheets that bear on environmental health, it is therefore better not even to try to share the scientific community’s state of knowledge, or ignorance, regarding possible health consequences of certain industrial exposures.

This sort of calculated refusal to disclose known and suspected risks of certain industrial compounds and processes, has become a pivotal issue in claims brought by disabled workers against such corporate giants as Dow Chemical, Johns-Manville, and Hooker Chemical. In these cases, the charge is 1) fraud, and 2) conspiracy to withhold information about human health risks, on the apparent rationale that cognizant people would not willingly elect to work around such things as the sterilizer DBCP or the carcinogen asbestos without protection against exposure. Since protection of this kind would be more costly to the employer than paying workers compensation (the typical remedy for work-place injury or disability), workers are now asserting that corporate greed prompts very calculated decisions by employers and third party chemical houses not to disclose health risks to innocent workers, and that such bad actors should not be immune from civil liability for their conduct.

As we enter the 1980s, these themes — fraud, conspiracy, cost-benefit — are fast becoming buzzwords in the area of job health and safety. Perhaps it is the enormity of the tragedy that forces us to grasp for shorthand buzzwords rather than dwell on the details of the small personal tragedies occasioned by toxic exposures on the job. But if we are to be effective in combatting these evils we must look at the specifics. We must document cases, measure air samples, learn to take sound occupational health histories, search far and wide for data and evidence and also for the allies whose support and encouragement are so vital.

In that regard, it may be instructive to examine some job health developments in one of the nation’s fastest growing industries, electronics and semi-conductor manufacturing. In California’s “Silicon Valley,” 26 percent of the work force is engaged in electronics work, and the overwhelming majority of production workers are women of childbearing age. Competition is fierce both for profits and for human talent. At the same time, while the industry projects an image of clean, light, advanced technology, the reality of much production work is a nightmare of toxic solvents, poisonous gases, and corrosive acids, to which workers are exposed daily with little or no personal protection and often under poorly ventilated conditions.

Two years ago I sent for a NIOSH pamphlet called “Know Your Solvent,” hoping it would provide me with basic information about at least one class of industrial hazards faced by friends and clients who work in “Silicon Valley.” I was dismayed to find that the pamphlet was essentially a series of bromides about being careful around solvents, and contained little discussion of acute or chronic health risks associated with specific exposures. Rather, the NIOSH writer advised, “When in doubt, ask your supervisor.” It struck me that either the pamphlet was a joke or the writer was terribly naive. Since when has it been efficacious for a concerned worker to ask her supervisor about the possible health risks of inhaling such common solvents as trichlorethylene, methylethyl ketone, 1,1,1-trichloroethane or xylene (frequently contaminated with benzene)? Indeed, several women who, following long-term exposure to toxic wastes coursing through a malfunctioning ventilation system, became hypersensitive to their environment, asked their supervisor early on about a possible relationship between their acute symptoms and their exposure to TCE vapors. In response to their inquiry they were told they were simply exhibiting female hysteria.

In electronics and semiconductor manufacture, solvents are essential to certain production processes. If we are to have the benefits of electronic technology, it appears inevitable that electronics will work with solvents, notably chlorinated hydrocarbons. This fact should not mean, however, that assemblers need to be subjected to toxic vapors strong and numerous enough to induce nausea and vomiting, headaches, dizziness, depression, menstrual irregularities, vision problems and kidney disorders, to name some of the problems now being documented. In theory at least, there are OSHA standards for exposure to each and every solvent used in this industry. Likewise, there are OSHA standards for the ventilation system that the employer must have to insure not only that these OSHA standards are not exceeded, but also that as a bottom line there are no exposures which result in human harm.

But while the principles of setting and complying with OSHA standards seem straightforward, there are a number of reasons why workplace hazards persist, in electronics as in many other industrial sectors. The benzene story may only be the beginning, in other words. In a short space the limitations of standards-setting and enforcement can only be catalogued, but that in itself may be useful. First, existing standards for industrial chemical exposure are based on what a hypothetical “healthy adult male” (under 30, 180 lbs.) is presumed able to tolerate over an eight-hour shift without adverse effect. This premise overlooks the difference in weight between American men of European stock on the one hand, and most minority workers and women on the other; it also fails to take into account that women, with proportionally more fatty tissue, may thus be much more vulnerable to assaults by fat soluble chemicals. In addition, it overlooks the fact that many workers, men as well as women, are not healthy anyway, and that factors such as speedup, noise, racism, sexism and other physical stressors make many of us something less than the superworkers the standards might conceivably protect. Further, the premise of an eight-hour exposure means that workers who customarily work a ten-or twelve-hour shift may be severely overexposed, even if the threshhold limit values specified in the standard are never exceeded. Again, with the exception of OSHA’s lead standard, existing standards do not consider possible reproductive risks of exposure. Attempts to bring this vital factor to bear on the question of industrial exposures have produced some frightening suggestions from industry, like the recent proposal by the California Manufacturers Association that reproductive risks be obviated by hiring senior citizens to work in toxic environments. Finally, unlike the benzene standard, most OSHA standards were adopted wholesale from industry when the Administration came into being in 1970. Never studied or scrutinized, neither have they ever been revised.

As new data emerge linking entire classes of chemicals with grave cancer risks, workers and their advocates will have to step up pressure for stronger standards, as industry’s resistance is likely to be massive. Job health advocates can advance the campaign for tighter standards by: 1) documenting acute health effects experienced during or after handling or inhaling the substance(s) in question; 2) documenting the types of controls and equipment that furnish protection from direct and indirect exposures; 3) requesting that NIOSH perform Health Hazard Evaluations, including health monitoring as well as site visits; 4) petitioning OSHA to begin the standards-setting process; 5) gathering evidence on the human toll taken by toxic exposure, in anticipation of the inevitable claim that stricter regulation will force massive economic dislocation, job loss and even bankruptcy.

In addition to the foregoing suggestions, we must bear in mind that even the most stringent OSHA standards will not take the place of rigorous shop-floor demands for a safe and healthful workplace. OSHA standards, even when they are enforced, represent a compromise between recommendations based on scientific research and those based on the political feasibility of adopting and enforcing a given standard. This most unpleasant fact of life in a capitalist society means that occupational health advocates must see OSHA regulations and OSHA’s enforcement program as necessary but hardly sufficient protective measures — a bottom line on working conditions, which can be improved by concerted activity on the shop floor. Such activity ranges from petitions to collective bargaining, from right-to-know campaigns to mandatory health monitoring and health and safety walk-outs.

None of these important campaigns will be won overnight. There will be heavy employer resistance and many workers will understandably hesitate to take risks, especially in unorganized industries, like electronics, where the assembly lines are staffed by workers who can find no other work and who work to survive. There comes a time, however, when the risk of speaking up may seem minor compared to the risks of disability or death from toxic chemical exposure. In its work with “Silicon Valley” workers, the Electronics Committee on Occupational Safety and Health (ECOSH) has seen a number of frightened and financially insecure people decide to take that risk, and clearly more will follow as evidence of some of the potential long-term risks of electronics work begin to emerge. In counseling workers about taking such a step, ECOSH stresses several points:

- All workers have an absolute right to know what substances they are working with and the risks associated with them.

- No one should be forced to choose between his or her job on the one hand and life and health on the other, nor should any worker, male or female, have to sacrifice reproductive capacity as the price of a job.

- Regulatory agencies respond in proportion to the clout wielded by those calling upon them, and unorganized workers must reach out for support if their demands are going to be heard.

- No rational capitalist will disclose the human health hazards of a profitable chemical product unless it pays to do so.

- No rational capitalist will clean up the workplace unless and until it pays to do so.

- The lives we save had better include our own.

>> Back to Vol. 12, No. 2 <<