This essay is reproduced here as it appeared in the print edition of the original Science for the People magazine. These web-formatted archives are preserved complete with typographical errors and available for reference and educational and activist use. Scanned PDFs of the back issues can be browsed by headline at the website for the 2014 SftP conference held at UMass-Amherst. For more information or to support the project, email sftp.publishing@gmail.com

Migrant Workers, Farmers, and the Mechanization of Agriculture: The Tomato Industry in Ohio

by Peter Downs, Bob Rice, John Vandermeer, & Katherine Yih

‘Science for the People’ Vol. 11, No. 3, May/June 1979, p. 7–14

Migrant Workers in Ohio

Summer in northern Ohio is Tomato Heaven. Migrant farmworkers from Florida and the Rio Grande valley in Texas move up to work the fields each summer. These workers, the backbone of much of the food industry, are offered housing with no inside plumbing—water must be carried from a common building. Light in rooms is fashioned from festooned extension cords and bare light bulbs. A hard rain changes the camp’s grassless grounds into a mud bath. For bending, stooping, and picking a hamperful of tomatoes (33 lbs.), a worker in northern Ohio gets anywhere from 19-25 cents, at least ten cents per hamper less than that received by workers in other states.

When Edward R. Murrow exposed a national television audience to the plight of migrant workers in his “Harvest of Shame” in 1959, the public was outraged. How, in this land of plenty, could an entire class of people be forced to live in conditions so base? The public outcry was for legislative action to end such shameful conditions.

Yet the scene in northern Ohio today remains remarkably similar to that depicted in Murrow’s “Harvest of Shame” 20 years ago. Legislation is never enacted for the powerless.

The Problems of the Farmer

If you were a tomato farmer in northern Ohio, you would not be likely to view the plight of the farmworker so sympathetically. While no one wants to see human beings forced into such a life, at the level of stark economic reality, the migrant is a cost of production. And labor costs are but one part of the equation that determines whether or not you make it each season. The farmer must purchase seed (or other planting material), machinery, fertilizers, and pesticides, in addition to labor. The amount of money a farmer must lay out each season grows each year. A utility pickup in 1959 averaged $2700, while in 1979 a similar pickup runs $6000, an increase of 120%. In 1959 a 60 hp tractor cost about $3500, while in 1979 the same size tractor costs $12,000, a 240% increase. But in 1959 the price paid to an Ohio farmer for a ton of tomatoes was $30, while in 1978 that same ton would bring $60, only a 100% increase. Costs to the farmer are rising faster than the money received for produce. This growing imbalance threatens to push more farmers off the land.

The situation was dramatized last year when farmers across the country joined the American Agriculture Movement and attempted to organize a strike. The national agricultural strike frequently made headlines and was even a regular feature of national television news. The American public became aware of the squeeze the farmers felt. The call for “parity”—price guarantees for agricultural produce that would at least meet the costs of production—publicizes the needs of farmers. Again the public outcry was for legislation, this time to save the farmer. Such legislation seems about as likely as the legislation called for to protect migrants in the late ’50’s. Effective legislation is never enacted for the powerless.

The Migrant Worker and Farmer in Conflict

The farmer’s view of migrant labor as a cost of production is an economic necessity. Any move to increase the political power of migrant labor is a threat to increase production costs for the farmer. There seems to be an inherent contradiction between labor (migrant workers) and “capital” (the farmer). If migrant workers demand more money for their labor or better housing or improved working conditions, costs of production for the farmer go up. But, as is always the case with those who have nothing to sell but their labor, such demands can only be effective with political power. And political power, for this class at this time, comes from a united front, a union.

In 1969 migrant farm workers in northern Ohio founded the Farm Labor Organizing Committee (FLOC). FLOC’s purpose has been to organize the workers into a tight unit capable of negotiating its position in the food industry. In the early seventies FLOC won contracts with several tomato growers. The contracts guaranteed a minimum price per hamper from those growers, and some minor concessions with regard to living and working conditions.

But the very existence of a union, as expected, caused much alarm on the part of the farmers. FLOC came to be viewed as one of the most important enemies of the farmers in their economic battle to stay alive. The conflict between farmer and migrant worker was clearly intensified by the presence of a union organization.

In mid-August of 1978, FLOC led migrant workers out on strike. Over 2,000 workers left the fields and refused to pick tomatoes. Many came to live in a “tent city” hastily set up by FLOC in Balmore, Ohio, No one knows exactly how effective the strike was, but it is estimated that from 10 to 30% of the tomato crop rotted in the fields.

Can one fail to appreciate the tragedy in the relationship between the daily struggle of migrants and the economic plight of farmers? Any gains made in living conditions for the farm worker spell disaster for the farmer. Keeping production costs down for the farmer almost certainly means the retention of subhuman conditions for the migrants.

The Migrant Worker and Farmer in Conflict—Revisited

A somewhat different picture of this human tragedy emerges if we begin the analysis from the other end, the consumer end. Ketchup cost 36¢ for a 26 oz. bottle in 1959, while in 1979 it costs 77¢. Tomato juice increased 237% in price over the same period. In short, consumers are paying a great deal more for tomato products now than they did twenty years ago, yet the farmer received only slightly more for his/her produce than in 1959. Obviously a middleperson is benefitting considerably.

If we statistically break down the gross receipts from the tomato industry by the proportion that goes to each group of recipients, a rather dramatic result emerges. Fully 83% of the gross receipts go to the cannery and retail outlets. The farmer gets 9%, the migrant laborer 4%, and the cannery worker 4%. In other words the people who produce the tomatoes (the farmers, migrant workers, and cannery workers) get 17% of the gross receipts, while those people who do not engage in production but merely own the production facilities get 83% of those gross receipts.

From this point of view it seems a bit strange to view the situation as a conflict between farmer and migrant worker. It would seem that the major conflict is between the owners of the production facilities (who get 83% of the gross receipts and do no work) and the people who produce the tomatoes (who get 17% of the gross receipts and do all of the work). But such an interpretation would imply that the farmer and the migrant laborer are in the same “class”‘ position, that is, their interests are the same. How convenient for those who own the canneries to have the migrants and farmers in conflict. Dividing the class that produces is an old trick, but one that is being played very effectively in northern Ohio.

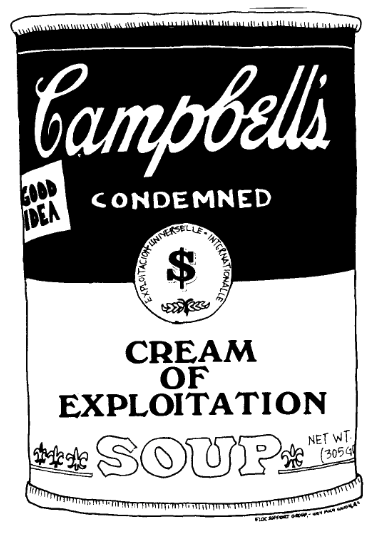

Having gone through an analysis similar to the above, FLOC changed its strategy from dealing only with the farmers who hire migrant labor to dealing more directly with the canneries. Thus, the strike last year was directed against those farmers who were under contract to either Libby’s or Campbell’s, the major producers of tomato juice in the area (tomato juice is made from hand-picked tomatoes because machine-picked tomatoes are much fleshier, so as to be resistant to bruising during harvest). One of the central demands of the strike was the FLOC be included as a third party in the annual contract negotiations between the canneries and growers. Efforts were made to include cannery workers as part of the strike and many walked off the job (although the cannery workers are organized under the Teamsters and were officially not in support of the strike—more on this later).

FLOC’s strike served to intensify some major economic contradictions that already existed in the tomato industry. One set of problems that the strike helped to bring out clearly stems from the trend towards mechanization.

The Final Solution: The “Almost Complete” Mechanization of the Tomato Industry

Before describing the specific effects of mechanization in the tomato industry, it is well to recall the general impact of mechanization on agriculture. When the first mechanical harvester was introduced in 1831, it was touted as a great work-saver: whereas earlier one person could harvest 1/2 to 3/4 an acre per day, after the introduction of the mechanical reaper, each person could harvest 6-8 acres per day. Recognized for what it was at its inception, a labor-saving technique, agricultural mechanization has retained its basic character to the present day. It is unimportant whether one says “displacement of the rural labor force to an urban labor force” or “great savings in labor costs”. Both statements refer to the same process: machines in the fields force the workers off the land.

Although less obviously a consequence of mechanization, massive changes in land tenure have also resulted. So-called economies of scale have been inevitably associated with industrialization of agriculture. For example, a holding of 40 acres might produce one ton of corn, which might sell for $400. Harvesting with hand labor would cost about $300 for the harvest, while a mechanical harvester requires about $20 for gasoline and upkeep. The catch, of course, is that a mechanical harvester costs about $40,000. But the harvester costs $40,000 whether your holding is 40 acres or 4000 acres. It is easy to see that mechanization puts large land holders at a distinct competitive advantage. The result is the gradual absorption of small holdings into large holdings, and today large holdings are usually the property of corporations. Indeed, mechanization put the small farmer into the same “class” position as the landless laborer—both are turned into proletarians: wage slaves and unemployed.

In an economy organized under the so-called principles of free enterprise, the social results of mechanization are three: small farmers are put out of business, farm laborers are put out of work, and corporate farmers are put into big profits.

Mechanization in the tomato industry takes on a variety of forms. Two specific forms are important for this analysis: the mechanical harvester and the evaporator. Mechanical harvesters, of course, cut down on labor costs dramatically, but they can’t harvest just any old tomato. Tomatoes, to be harvested mechanically, must have tough skins and, consequently, have mealy insides. They must also ripen more closely to the same time than if they were to be hand-picked. These constraints are extremely important because tomatoes with thick skins and mealy insides cannot be used to make tomato juice—they are presently used exclusively in the production of ketchup. Mechanical tomato harvesting cannot take over completely if there is a need to produce tomato juice.

The evaporator constitutes a new procedure in the processing of tomatoes. Its purpose is to boil away water from cooked tomatoes until only a thick paste is left. The paste can be mixed later with water—using complicated technology—to obtain juice. Thus, rather than producing ketchup directly from machine-picked tomatoes and juice from hand-picked tomatoes, the properly developed evaporator changes the process to producing both ketchup and juice directly from tomato concentrate. The concentrate is made from machine-picked tomatoes. The critical point is that the evaporator eliminates the necessity for hand-picked tomatoes. At the present time evaporator processing has not yet been perfected, at least for the varieties of tomatoes grown in Ohio.

Thus, the combination of the evaporator and the mechanical harvester will put the migrants (in the tomato industry) completely out of work. At the same time, it will generate economies of scale that will force smaller farmers to sell out to larger farmers. According to Ruben Peterson, field supervisor at Libby’s plant in Leipsic, Ohio, “with the increase in mechanical harvesting, the smaller farmer will disappear.”

The increased exploitation brought about by mechanization does not stop with the growers and pickers. Workers at the level of processing as well will feel the pressures of the new technology. The prospective amalgamation of the juice- and ketchup-production processes through the use of the evaporator and machine-harvested tomatoes will result in an overall reduction of jobs in the canneries. Consider Libby’s two midwest canneries. The one in Leipsic, where the evaporation process is being attempted, presently operates two production lines, one for juice and one for ketchup. The one in Kokomo, Indiana, produces only juice, exclusively from hand-picked tomatoes. If the evaporation process is successful, the plant at Kokomo will be shut down, and juice- and ketchup-production in Leipsic combined—three production lines will effectively be condensed to one. In addition, the new machines will concentrate production into a short period. Harvesting machines go through fields only once, taking everything, as contrasted with human pickers who work a field several times as the crop ripens. The evaporator is expected to process tomatoes at a much greater rate than the old methods. This period of intensified production should coincide with the time migrant pickers come north for work. It is clear that canneries can profit by a sudden shift to mechanization: migrants coming north to pick will find themselves part of a larger-than-usual labor pool serving the canneries, and workers will be in no position to bargain for anything.

THE STRIKEOn 20 August, 1978, farmworkers in Ohio decided to strike the entire tomato industry. This important decision was reached only after repeated attempts by the farmworkers to meet with growers and cannery officials had failed. Although some growers were willing to recognize the union and offered some wage increases, most followed the lead of the canneries and boycotted the meetings. By striking the entire tomato industry, the farmworkers were telling grower and cannery alike that only a contract signed by both these parties would get farmworkers back to work. After a few weeks, many farmers were willing to enter negotiations. With over 2000 farmworkers on strike, almost thirty percent of the tomato crop was rotting in the fields. Many farmers now face economic ruin. The canneries, however, remain adamant in their refusal to negotiate with the farmworkers, seeking instead to fully mechanize the tomato harvest (see article). This stand by the canneries is prolonging the strike. Some farmers have gone beyond some of FLOC’s demands (see below), offering as much as 50¢ per hamper. But farmworkers remain firmly committed to getting a contract signed by the canneries. FLOC’s demands: Coverage of Pickers

Coverage for Crew Leaders

|

The Strike and its Impact

The strike was directed against only those farmers under contract to either Libby’s or Campbell’s, the major producers of tomato juice. The canneries reacted swiftly. Libby’s immediately filed a $1.08 million suit against FLOC for losses due to the strike. Also, within a month they assembled a giant new “evaporator” at their Leipsic, Ohio plant. According to field supervisor Ruben Peterson, the research department is under a great deal of pressure from management to perfect the evaporator process by the Spring of 1979. When asked why, he replied “labor problems”. (If they are successful in perfecting this process, they won’t need hand-picked tomatoes at all.)

FLOC was well aware that its confrontation with the canneries would reinforce existing trends toward mechanization. This gave greater urgency to their organizing efforts, so that workers would have some control over the implementation of machine production. FLOC is not opposed to mechanization, rather it welcomes the advent of machines in the field, but on the workers’ terms. That is, the introduction of machines in field work must go hand-in-hand with training displaced workers for new jobs and supporting them and their families until new jobs are secured. Naturally the expenses for this must be covered not by the taxpayers, but by the canneries, whose profits have come from the labor of those workers.

FLOC recognized that mechanized farming threatens not only the migrant workers, but also the farmers. Thus for the last few years, it has tried to work with farmers against the canneries. This has been largely a failure. This failure was felt most acutely during the strike when farmers threatened strikers with guns and attacked them with baseball bats and even pesticides. Just as industrialists benefit from racial divisions within the working class, pitting black against white, nationality against nationality, so the canneries benefit from the division between the growers and the migrants.

A major obstacle to uniting the farmer and the migrant is the traditional individualism of the American farmer. The myth of the independent family farmer is just that, a myth, but a potent myth. Commercial tomato farmers are actually just agricultural laborers who happen to supply land with their labor. But they are laborers with a particular history, a particular ideology, a particular culture of “independence” and individualism, factors which contribute to the difficulties farmers have in organizing themselves and make it especially easy to splinter their movements (remember the American Agricultural Movement).

The relationship of a farmer to the cannery is always that of an individual. The acreage a farmer contracts for with Libby’s, for instance, is based on his/her yield per acre average over the previous three years. In 1978 these amounts ranged from five to two hundred acres. The contracted acreage and the individual’s “average yield” then set a limit on the quantity of tomatoes (the tonnage) a farmer can bring to Libby’s. A farmer can exceed his/her contracted tonnage by up to 10%. If s/he produces more than that, s/he must first offer the excess to Libby’s, and if Libby’s refuses the excess, it may be sold on the open market, with Libby’s permission.

This loss of control over what happens to their crop is only one aspect of the farmer’s loss of control over the entire agricultural production process. The tomato plants themselves are owned by the canneries. Some farmers are given seeds in the Spring, but most are given plants which the cannery starts earlier in the South (Libby’s starts theirs in Georgia), and then bring up to Ohio. Once the plants are in the ground, representatives of the cannery inspect every farm once a week, looking for diseases, insects, etc. They then tell farmers what and when to spray.

THE BOYCOTTFaced with the continued intransigence on the part of the canneries, FLOC decided it was necessary not only to maintain, but to increase the pressure on the canneries year-round—not just at harvest time. Towards this end, farmworkers prepared an international boycott of the products of the two largest tomato canneries in northern Ohio: Campbell’s and Libby’s. The boycott was kicked off on 25 January with press conferences across the country and a mass picket (involving over 70 people) at a Kroger’s store in Ann Arbor, Michigan. FLOC is coordinating its boycott with INFACT (Infant Formula Action Coalition) which is boycotting Nestle products, which includes those made by Libby, a Nestle subsidiary. The two organizations are giving each other mutual support. BOYCOTT the following companies and their products: Libby-McNeill-Libby -All Nestle’s products (Nestle’s is the parent company of Libby-McNeill-Libby) -All vegetables, fruits, meats, and juices with the Libby’s label. Campbell’s -Campbell’s Soup -Swanson frozen prepared dinners and meats -V-8 vegetable juice -Efficient food service products -Recipe pet food -Hanover Trail restaurants -Franco-American products -Lexington Gardens retail garden centers -Pepperidge Farm products -Granny’s Soups -Bounty canned chili and entrees -Godiva chocolates -Pietro’s Gold Coast pizzas -Delacre cookies and pastries -Herfy’s Restaurants -Kia-ora food products -VIasic The effectiveness of the boycott is increased when company offices are flooded with letters from angry consumers, demanding justice for farmworkers. Write to: Douglas B. Wells, Pres. Libby, McNeil and Libby 200 S. Michigan Chicago, IL 60604 D.Y. Robinson, Director Consumer Affairs Campbell’s Soup Camden, NJ 08101 Tell them you’re boycotting their products and why. Send a copy of your letter to: FLOC 714 1/2 South St. Clair Toledo, OH 43609 If you have any questions, please write to FLOC or Ann Arbor Science for the People FLOC Support Committee 4104 Michigan Union Ann Arbor, MI 48109 |

When it comes to the migrant workers hired by the farmers, the control of the canneries is just as great. The wages and living conditions of the migrants are largely set by these canneries in their yearly negotiations with the growers. Once the evaporator and reconstitution process are ready, Libby’s will effectively pressure growers to change over to machine harvesting. Not only will this result in the loss of jobs for thousands of migrant workers, but it will also cost many farmers their livelihood. In 1978 the number of acres individual farmers had in tomatoes ranged from five to two hundred. The field supervisor of Libby’s Leipsic factory estimated that for a mechanical harvester to be profitable one would need one acre of tomatoes per $1000 of machinery, and the smallest harvester costs about $40,000! Therefore, if a farmer is to stay in business, s/he needs a minimum of 40 acres of tomatoes.

Farmers are thus in a very precarious position. They have effectively lost their independence, and many are in danger of losing their livelihood completely. This helps explain the violence of their reaction to the FLOC strike. Their present position, though precarious, is maintained by the even greater exploitation of farmworkers. Growers can persist in their position only if the growing strength and power of migrant farmworkers is curtailed. Having lost substantial control over their own work, farmers fear ending up in the same position as the migrants. Growers have already expressed the fear that if FLOC wins its strike, they will be represented at the bargaining table by a union of migrant workers.

Also contributing to disunity is the fact that cannery workers themselves either have failed to recognize that all workers in the tomato industry are exploited by the canneries, or they have failed to realize that the workers’ only weapon against exploitation comes from unity. The workers at the Libby’s plant in Leipsic are organized under the Teamsters. FLOC arranged a meeting with the Teamsters local last summer, well before the strike, to convince them to honor the planned picket line. The Teamsters stated that this was impossible or impractable, since such sympathy strikes were forbidden in their contract. The Teamster hierarchy was seen enforcing this position when, during picketing at the cannery, a Teamster official, apparently sent from outside the area, was seen escorting cannery workers across the picket line. According to one FLOC member, FLOC did receive support from many of the Chicano workers, some of whom joined the picket line and indeed got fired, but many of the Anglos seemed hostile to the strikers.

This division between cannery workers and field workers plays right into the hands of the canneries. It guarantees that the strike will be longer and costlier for the workers. The quickest way to end the strike would be if all the cannery workers went out, during the harvest, in solidarity with the field workers. When workers unite and successfully struggle with corporations for control of production, small farmers will also realize that their only chance for survival lies in an alliance with the workers, as opposed to slow death by siding with the canneries.

FLOC’s struggle is clearly important for everyone whose life is influenced by technology. One of the major issues farmers and farm workers are facing is mechanization. Who will control its implementation, whom will it benefit, the corporations and their owners, or the broad masses of working people? FLOC’s stand, that mechanization must be implemented in such a way as to benefit workers, deserves our full support.

Through various organizing efforts (such as national boycotts), we can intensify the struggle between those who produce the food and those who own the production facilities, eventually providing for the producers to take control over those means of production.

The authors are members of the FLOC support group of Ann Arbor Science for the People. They have been working in alliance with the Farm Labor Organizing Committee (FLOC) for the past year.